What is paint protection film?

It is a high-performance new environmentally friendly film, which is widely used in the automotive beauty maintenance industry, a commonly known as transparent painted protective film. With super toughness, the car can be painted with air after loading, and the lacquer surface is permanently protected. Introduce you from both structural and materials.

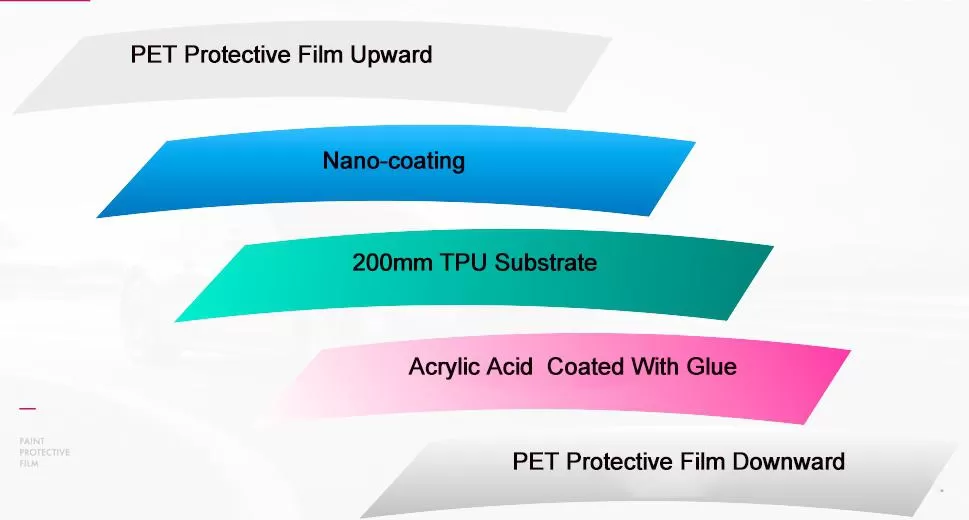

FIRST STRECTURE

First layer,PET protective film, protect the coating, remove before cutting the film

The second&three&four layers are integral, respectively:

Second layer,thermal repair coating ,about 0.8-1 mil

Third layer,substrate (TPU / TPH / PVC and so on), about 6 mils

Fourth layer,pressure sensitive glue

Tifth layer,PET protective film

SECOND MATERIAL

① PET is simple, so I won’t introduce it .Let’s have a look at the coating materials, substrates and glue materials.

②Talk about glue first. The glue is simple and basically good now. There are three ways to distinguish it:

1.Smell, pungent bad.

2.Pinch. After you get rid of your hand, your hand sticks bad.

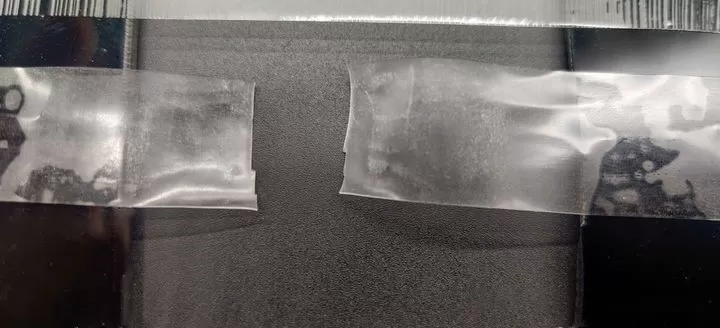

3.Pull the glue face up, press the film with your left hand, and pull the nail with your right hand ten times. Observe whether there are obvious bright spots on the glue surface. If there are any, it means degumming. If the film is degummed, it means that the film will remain glue in the future.

Q: Do you want to tear it after pasting? The film needs to be repaired if it is scratched . If the film is torn off after leaving the glue, it will hurt the car paint, which is also very troublesome.

③ The substrate

The most original base material is PVC. The cost of PVC is relatively low. This material is generally used for wrap viny film. Later, TPU opened the door of the PPF industry and replaced PVC to truly realize the core functions of the protective film, such as scratch resistance, bump resistance and collapse resistance. TPU is a thermoplastic polyurethane elastomer. It is divided into aromatic and aliphatic, aromatic yellowing, fast aging, aliphatic non yellowing, slow aging.

With the increase of people’s understanding of car ppf films, the demand is expanding. In order to meet the needs of different consumers, TPH car clothes appear, namely total petroleum hydrocarbons.

④ The coating is not only the coat of TPU, but also the most “scientific and technological” part of PPF. Because it can repair scratches, it has become the biggest “selling point” of films. The core function of the coating is to give the densest protection to TPU, and scratch repair is also to protect TPU, which is the production logic of car film. (TPU protects the car paint from external force, and the coating protects TPU from climate and environment). At present, the coatings on the market are divided into thermal repair coating and self-healing coating (second repair).

Which one is better? Responsibly, thermal repair is better. And why?

The repair process is actually the reaction on the coating surface. Any chemical reaction needs to be most active at a specific temperature. The reaction temperature of the thermal repair coating is about 60 degrees, and the reaction temperature of the second repair is even lower than the normal temperature, that is, the thermal repair coating is in a stable state at normal temperature, while the second repair coating is in an active state, and the chemical reaction will lose its function after the reaction, In other words, the second repair product loses the repair function earlier than the hot repair product. In addition, the hot repair coating is thicker and more durable than the second repair coating. The repair durability of the actual test hot repair is dozens of times that of the second repair.

Both TPU and TPH have hot repair and second repair. Now that you know that you must choose the type of TPU hot repair, is the hot repair TPU good? You don’t have to look at the softness and density of the coating.

Why first? TPU has very strong tension, and coating protection TPU also needs a certain toughness. It is accompanied by a certain tension during construction. Therefore, the softness of the coating is very important, otherwise the coating will break and form lines. This leads to the rapid yellowing, water spots, fracture and other problems of the car clothes.

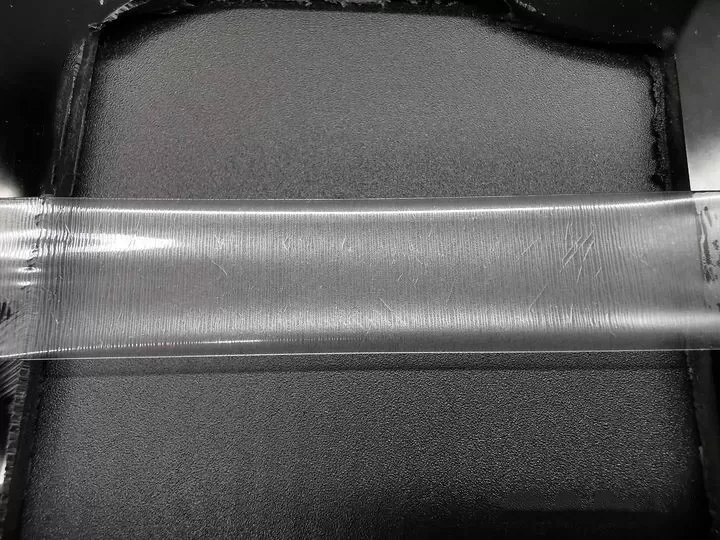

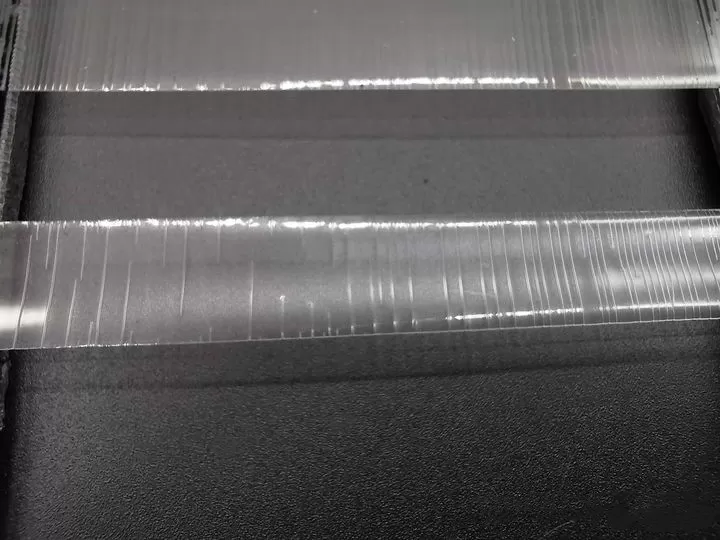

Consumers can tell whether the film is good or bad by holding it in their hands. We provide a simple and reliable method. Cut a small strip of film to be tested (2cm wide and 10cm long) with an art knife and stretch it slowly. Action Essentials: slow and careful observation;

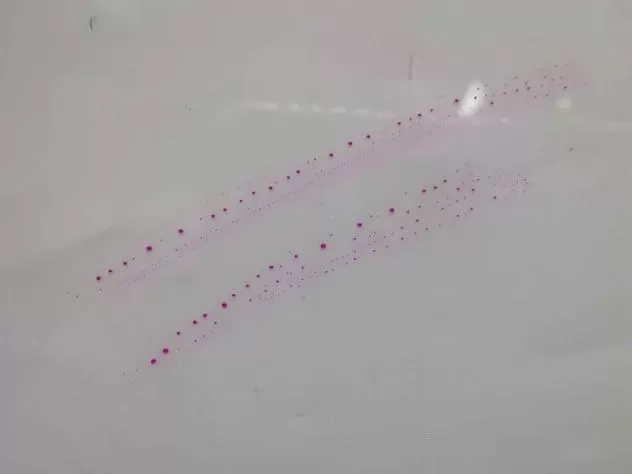

Performance of high-quality film: when the film is stretched to about 2 times, the lines begin to appear. The lines appear slowly, very thin and dense, about four times the length, and all the lines are displayed, very detailed. As shown in the figure:

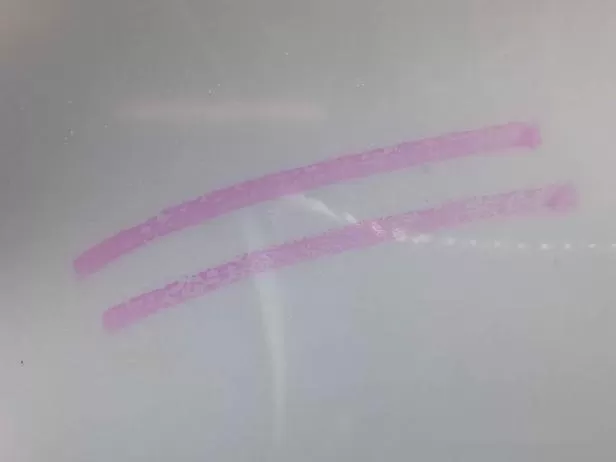

General film performance: when the film is stretched to less than 2 times, the lines begin to appear. The lines are cracked and the gap is large. With the sound of fracture, the distance between lines is large, and the coating feels hard. As shown in the figure:

In addition to the lines, you can also feel the coating by touching it by hand, which requires the hand feeling. The relatively soft surface of the high-quality film feels astringent. The surface of the poor film is very hard, the surface is smooth and has strong water splashing ability. You can draw it with a watercolor pen, which indicates that the water splashing ability is poor, and the beads coagulate immediately after painting indicates that the water splashing ability is very strong, and the water spots with strong water splashing ability are very easy to appear.

FOR MORE NEWS:

Website:www.kpalautomotive.com