Car coat film, also known as car paint protection film, its function is similar to the cell phone case and protective film, stick on the car to resist minor scuffs, scratches, etc..

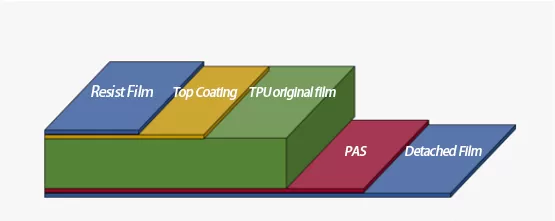

Structurally, the car coat film is composed of upper and lower layers of release film, functional coating, glue and TPU base film, of which TPU base film needs to be transparent, anti-UV, heat and aging resistant, soft and stretchable, which means that the car coat base film has very high requirements for TPU raw materials, and good invisible car coats basically use aliphatic polycaprolactone TPU. KPAL, as a professional PPF brand company, uses aliphatic polycaprolactone TPU as the base film.

Why Have to Use Aliphatic Polycaprolactones TPU?

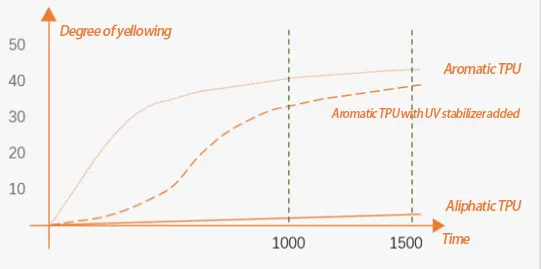

This is because the car coat must have high resistance to yellowing, high adhesion, high transparency, and aliphatic resistance to yellowing is far better than aromatic, while the density of aliphatic arrangement is several times that of aromatic, making the coating & adhesive layer can be firmly adsorbed on after coating, contact up to 30,000, not easy to fall off and separate, not easy to blister and warp, more durable protection performance, higher transparency.

Mainstream brands at home and abroad are using aliphatic TPU as the base material for car coats to achieve durability, stain resistance and yellowing resistance. Polycaprolactone is chosen because it can take into account high tensile resilience and long-cycle heat aging performance, good tensile resilience, which is conducive to downstream construction and the final wrapping effect after the car is attached.

Are There Many Types of TPU?

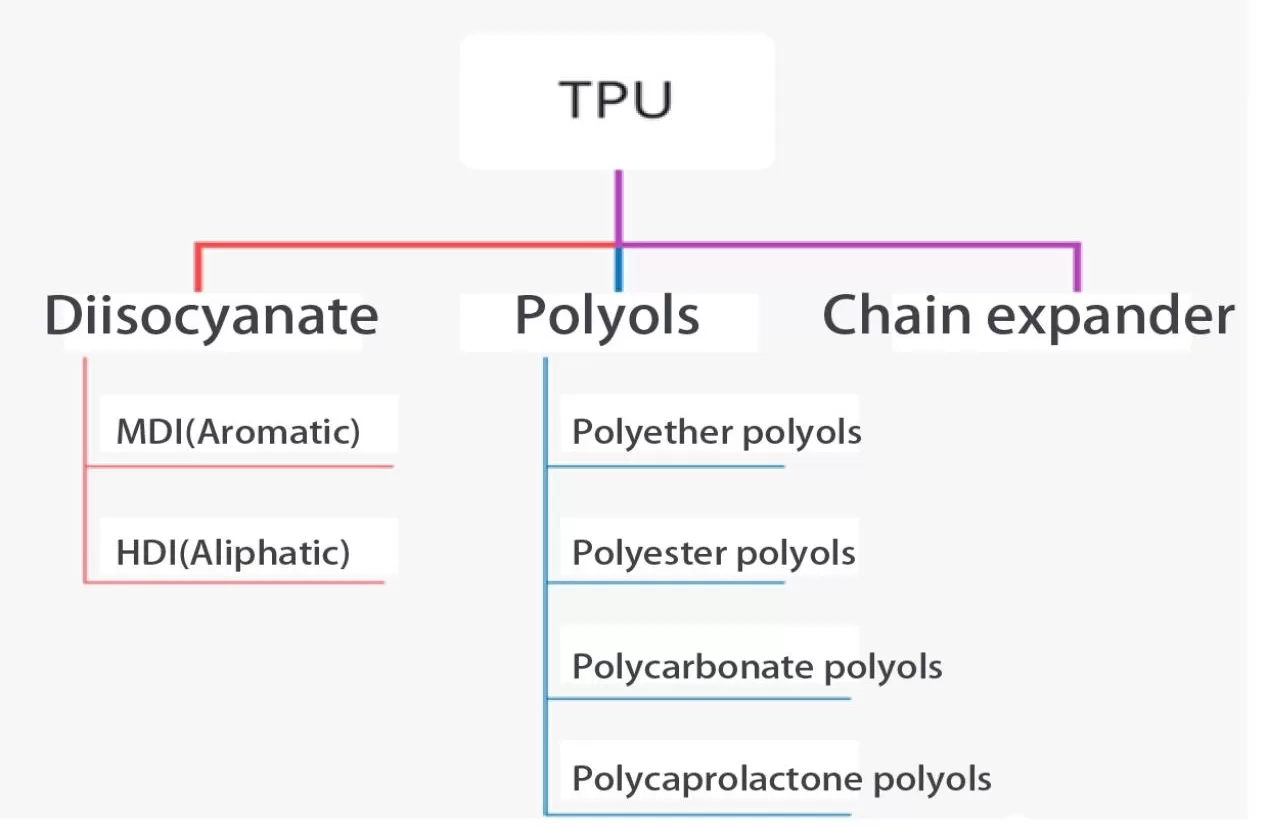

TPU is a polyurethane thermoplastic elastomer, a multiphase block copolymer composed of diisocyanate, polyol, and chain extender, and there are many types of TPU according to the different components of the synthetic monomer.

1: Aromatic TPU, aliphatic TPU according to diisocyanate type.

2: According to the type of polyol, there are: polyester TPU, polyether TPU, polycaprolactone TPU, polycarbonate TPU.

Combined with the above diagram, there can be at least 8 combinations of diisocyanates and polyols, which means there can be at least 8 subdivision types of TPU. It is worth noting that they all have similar faces and all look pretty much like transparent particles to the naked eye.

How to Distinguish TPU Type?

Infrared spectroscopy is the most accurate and convenient method to distinguish TPU types. In addition, cleavage mass spectrometry is also possible.